-

HG series multi-function standard source and calibrator

-

MGY/DO30 Series Calibrator/Trimeter Calibrator

-

Three-phase/single-phase electric energy meter calibration device

-

Insulation resistance meter (megger) calibration device

-

High voltage/ground resistor (device/box)

-

AC and DC high current standard source/welding machine calibrator

-

Clamp ammeter calibration device

-

GZC series petrochemical measurement and control instruments

-

HGZW series dyeing, weaving and weft trimming machine

-

other products

-

DO30 series three-meter/multimeter calibrator

HG-1000 electric welding machine field calibrator

The HG-1000 electric welding machine field calibrator (hereinafter referred to as the calibrator) is based on the calibration regulations JJG124-2005 "Calibration Regulations for Ammeters, Voltmeters, Power Meters and Resistance Meters",

- Product description

-

I. Overview

The HG-1000 electric welding machine field calibrator (hereinafter referred to as the calibrator) is based on the calibration regulations JJG124-2005 "Calibration Regulations for Ammeters, Voltmeters, Power Meters and Resistance Meters",

Calibration equipment designed in accordance with the requirements of JJG (Aerospace) 38-1987 "Verification Procedures for DC Standard Current Sources" and JJG (Aerospace) 51-1999 "Verification Procedures for AC Standard Current Sources". Mainly used to verify the voltage, current meter and output of various electric welding machines (such as AC manual arc welding machines, argon arc welding machines, secondary protection welding machines, DC welding machines, submerged arc welding machines, spot welding machines, etc.) accuracy. Generally, welding machines work under high current conditions, and the disassembly and assembly of the voltage or current meter are complicated. The accuracy of the welding machine indicator instrument will directly affect the welding quality. Our company designed a calibrator based on this characteristic of the welding machine, which can measure the cross current on site. The DC current is 1000A (the current size can be customized according to user requirements), the AC and DC voltage is 1000V, and it can accurately display the waveform of the output voltage and current of the welding machine. There is no need to disassemble or assemble the welding machine instrument. It has high accuracy, good stability, safe and convenient use, and is an ideal calibration equipment for welding machines.

2. Technical characteristics

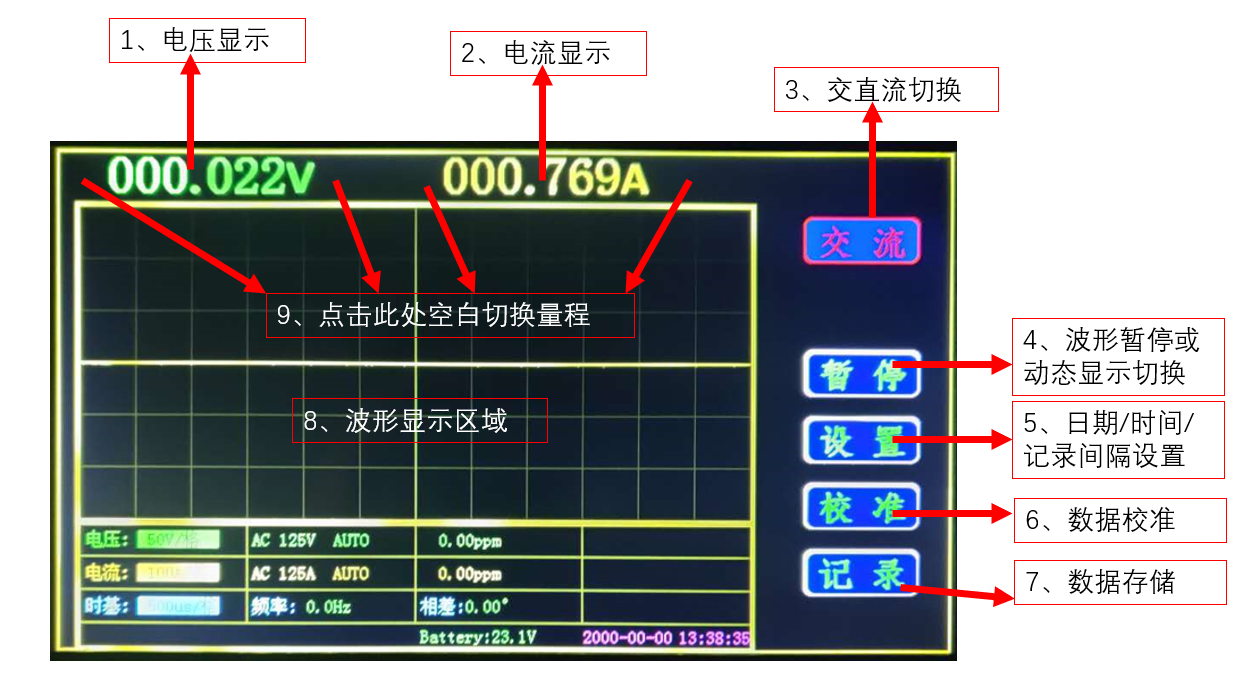

2.1 The calibrator is a six-and-a-half-digit display, highly stable, safe and reliable on-site measurement instrument. It adopts LCD color touch screen display and can display AC and DC current, voltage, waveform and other parameters on the same screen.

2.2 The calibrator uses advanced circuits dedicated to instrumentation and high-precision integrated circuit chips to ensure the measurement accuracy and reliability of the calibrator.

2.3 The calibrator has a wide measuring range and uses imported sensors. The instrument has good thermal stability and high reliability when operating at large currents.

2.4 The calibrator adopts a variety of software and hardware anti-interference measures and digital compensation technology to ensure that the instrument is not affected by the harsh environment on site when in use.

2.5 The calibrator can perform online on-site calibration of voltmeters, ammeters and voltage and current output waveforms on welding machines below level 0.5. It is lightweight and easy to carry.

2.6 The calibrator has a USB interface and can be read from a USB flash drive to save data.

3. Technical indicators3.1 AC and DC current measurement range: 0~1000A, measurement accuracy: ± (0.1% of reading value + 0.05% of full scale)

AC and DC voltage measurement range: 0~1000V, measurement accuracy: ± (0.07% of reading value + 0.03% of full scale)

3.2 Can display AC voltage and current waveforms and DC voltage and current trend graphs, and the measurement frequency can reach 100kHz

3.3 Self-powered, equipped with 24V lithium battery pack inside, capacity 5AH

3.4 Ambient temperature: -25℃~ 50℃

3.5 Weight: 8Kg

4.1 Turn on the power switch, the calibrator will automatically enter the measurement screen, and the range will be automatically converted. The functions of each part are as shown in the figure below:

4.2 Press the "Record" button. When it turns red, it means the device is automatically saving data (recording interval is 5s), and the data storage space is at least 2G.

4.3 Data reading needs to be connected to a computer (test data is stored in the Record folder by default).

Note: The internal clock is powered by a battery. If the time display is abnormal, replace the motherboard CR2032 lithium button battery.