-

HG series multi-function standard source and calibrator

-

MGY/DO30 Series Calibrator/Trimeter Calibrator

-

Three-phase/single-phase electric energy meter calibration device

-

Insulation resistance meter (megger) calibration device

-

High voltage/ground resistor (device/box)

-

AC and DC high current standard source/welding machine calibrator

-

Clamp ammeter calibration device

-

GZC series petrochemical measurement and control instruments

-

HGZW series dyeing, weaving and weft trimming machine

-

other products

-

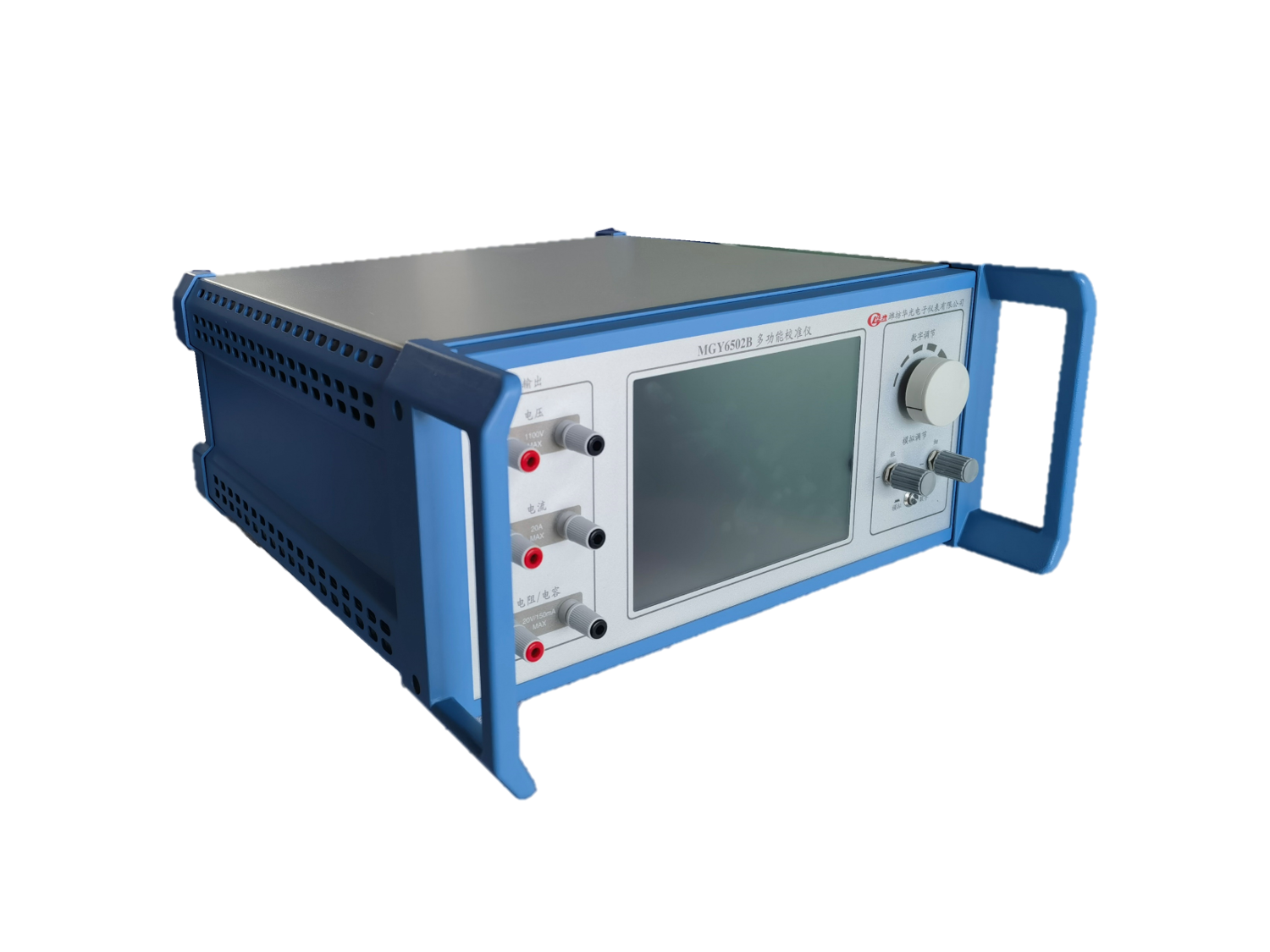

DO30 series three-meter/multimeter calibrator

SHZ-D constant speed source 2023 improved model

The SHZ-D type constant speed source is an upgraded model of our factory's original SHZ-D type constant speed source. It has a more intuitive display method, a more prominent silent effect, and a lighter weight. It can fully meet the needs of various normal-axis and off-axis hand-cranked models. Calibration requirements for megger and ground resistance meter. Driven by a stepper motor, the starting speed is 120 rpm and 150 rpm. The designed maximum speed is 250 rpm. It can be set arbitrarily through the speed control switch, and the speed does not fluctuate with load changes.

- Product description

-

1 Overview

SHZ-D constant speed source (hereinafter referred to as SHZ-D) is a special product designed and produced according to the technical requirements of JJG622-97 "Verification Regulations for Insulation Resistance Meters" and JJG366-2004 "Verification Regulations for Grounding Resistance Meters". It is produced by our factory An upgraded model of the original SHZ-D constant speed source, with a more intuitive display, more outstanding silent effect, and lighter weight, which fully meets the calibration needs of various positive-axis and off-axis hand-cranked megohmmeters and ground resistance meters. . This instrument combines the characteristics of various domestic constant speed sources, combined with user opinions, and is driven by a stepper motor. The starting speed is 120 rpm and 150 rpm. The designed maximum speed is 250 rpm, which can be set arbitrarily through the speed control switch. And the speed does not fluctuate with load changes. The light touch switch and coaxial balancing device integrate the control system and work, making it easy to operate and reliable in performance.

2 Main technical indicatorsSpeed range: 100 ~ 250 rpm

Fixed speed point: 120 rpm, 150 rpm

Accuracy: ±1 turn

Operating voltage: 220V ± 22V 50Hz ± 5Hz

Power consumption: 100W

Overall dimensions (mm): 385×305×95

Weight: 10kg

3 Working principleThe microcontroller and crystal oscillator generate a PWM signal that matches the motor speed. The start key and the speed adjustment key are combined into a multi-function key to jointly complete the starting speed and step speed adjustment functions. The PWM signal generated by the microcontroller is amplified by the drive circuit and directly drives the stepper motor, which drives the motor. The speed of the stepper motor is determined only by the frequency of PWM and has nothing to do with the supply voltage. Therefore, its rotational speed does not change with changes in load.

4 How to use

4.1 Structural diagram

(1) Speed display (2) Speed adjustment and start control (3) Power socket and switch

(4) Locking knob of the meter under inspection (5) Coaxial balance joint (6) Nylon pressure pad

(7) Lift adjustment knob and motor level adjustment knob (8) Lift table

(9) Tilt adjustment Note: (7) Actual two knobs

5 things to noteIf the motor loses synchronization during use, press the "Start/Stop" button in time, readjust the fixed position of the megohmmeter and then start again, and it will work normally. When calibrating megohmmeters and ground resistance meters with special specifications, the meter to be tested should be in an open circuit state before starting the instrument.