-

HG series multi-function standard source and calibrator

-

MGY/DO30 Series Calibrator/Trimeter Calibrator

-

Three-phase/single-phase electric energy meter calibration device

-

Insulation resistance meter (megger) calibration device

-

High voltage/ground resistor (device/box)

-

AC and DC high current standard source/welding machine calibrator

-

Clamp ammeter calibration device

-

GZC series petrochemical measurement and control instruments

-

HGZW series dyeing, weaving and weft trimming machine

-

other products

-

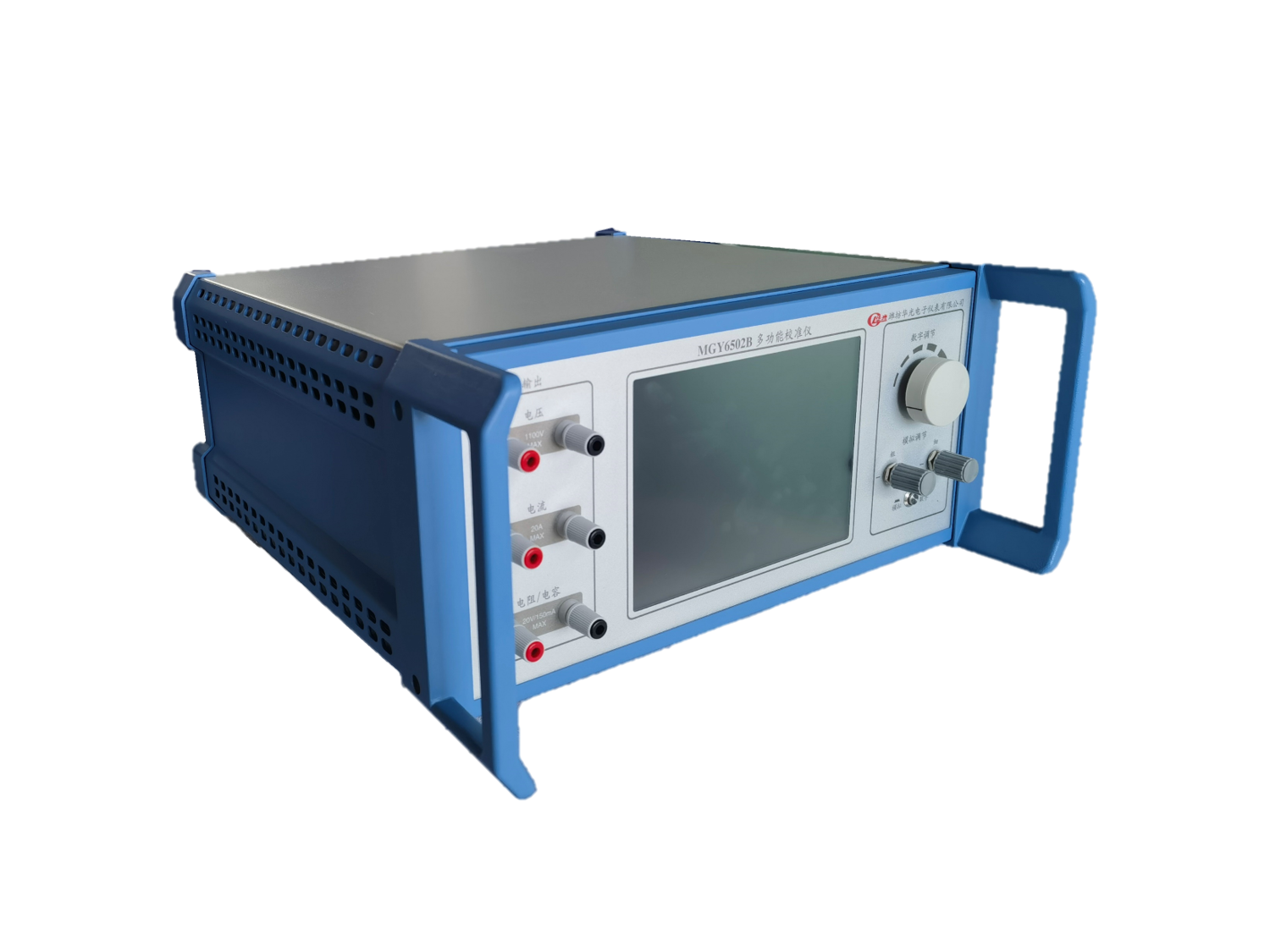

DO30 series three-meter/multimeter calibrator

CHT2000 charging and demagnetizing machine

CHT2000 charging and demagnetizing machine (abbreviated as magnetizing machine) is a thyristor voltage-regulating and current-regulating charging and demagnetizing equipment developed and produced using new technologies, new materials and some imported components. Mainly suitable for magnetizing and demagnetizing a pair of pole permanent magnets. This equipment has the characteristics of reasonable circuit structure, large carrying power margin, automatic control of magnetization time, and safety protection measures.

- Product description

-

1. Purpose and characteristics

CHT2000 charging and demagnetizing machine (abbreviated as magnetizing machine) is a thyristor voltage-regulating and current-regulating charging and demagnetizing equipment developed and produced using new technologies, new materials and some imported components. Mainly suitable for magnetizing and demagnetizing a pair of pole permanent magnets. This equipment has the characteristics of reasonable circuit structure, large carrying power margin, automatic control of magnetization time, and safety protection measures. It is widely used in the production and maintenance of electrical instruments in industrial and mining enterprises, scientific research institutes, electric power, railways, military units, schools and other units.2. Main functions

2.1 Charging and demagnetizing tooling equipment: The fixture consists of an adjustable frame and an adapting magnet (referred to as an iron gauge), which can be used for charging and demagnetizing most pointer instrument magnets. For special purposes, manufacturers can customize other fixtures.

2.2 Magnetization function: You can choose timed magnetization or continuous magnetization respectively. The time range of timed magnetization: 0-1 second, you can set it arbitrarily within this range, and the time range can be extended if necessary. When selecting continuous magnetization, the magnetizing current can be continuously adjusted, and the ammeter will indicate the magnitude of the current.

2.3 Demagnetization function: When selecting demagnetization, press the start key to demagnetize, and press the stop key to end the demagnetization work.

2.4 Prompt display: Turn on the power switch and the red indicator light will light up, indicating that the power of the whole machine is connected. When the function selection switch is placed in the magnetization position, the green indicator light will light up, indicating that the whole machine is in the magnetizing function state; when it is placed in the demagnetization position, , the yellow indicator light is on, indicating that the whole machine is in the demagnetization function. When adjusting the magnetizing current, the ammeter on the equipment panel indicates the size of the magnetizing current, and the current size can be adjusted according to the magnetizing effect.3. Technical parameters

3.1 Power supply requirements: sine wave AC voltage 220V±10%

Frequency 50Hz±1Hz

Power consumption is about 2500VA

3.2 Applicable environmental conditions: ambient temperature 0-40℃

Relative humidity <80%

3.3 Length of the object to be charged and demagnetized: <70mm

3.4 Cross-sectional area of the magnetized object: <80*60(mm)

3.5 Overall dimensions of the complete machine: length × width × height 580*350*320 (mm)

3.6 Weight: The main unit is about 50kg, and the accessories are about 10kg. (30)