-

HG series multi-function standard source and calibrator

-

MGY/DO30 Series Calibrator/Trimeter Calibrator

-

Three-phase/single-phase electric energy meter calibration device

-

Insulation resistance meter (megger) calibration device

-

High voltage/ground resistor (device/box)

-

AC and DC high current standard source/welding machine calibrator

-

Clamp ammeter calibration device

-

GZC series petrochemical measurement and control instruments

-

HGZW series dyeing, weaving and weft trimming machine

-

other products

-

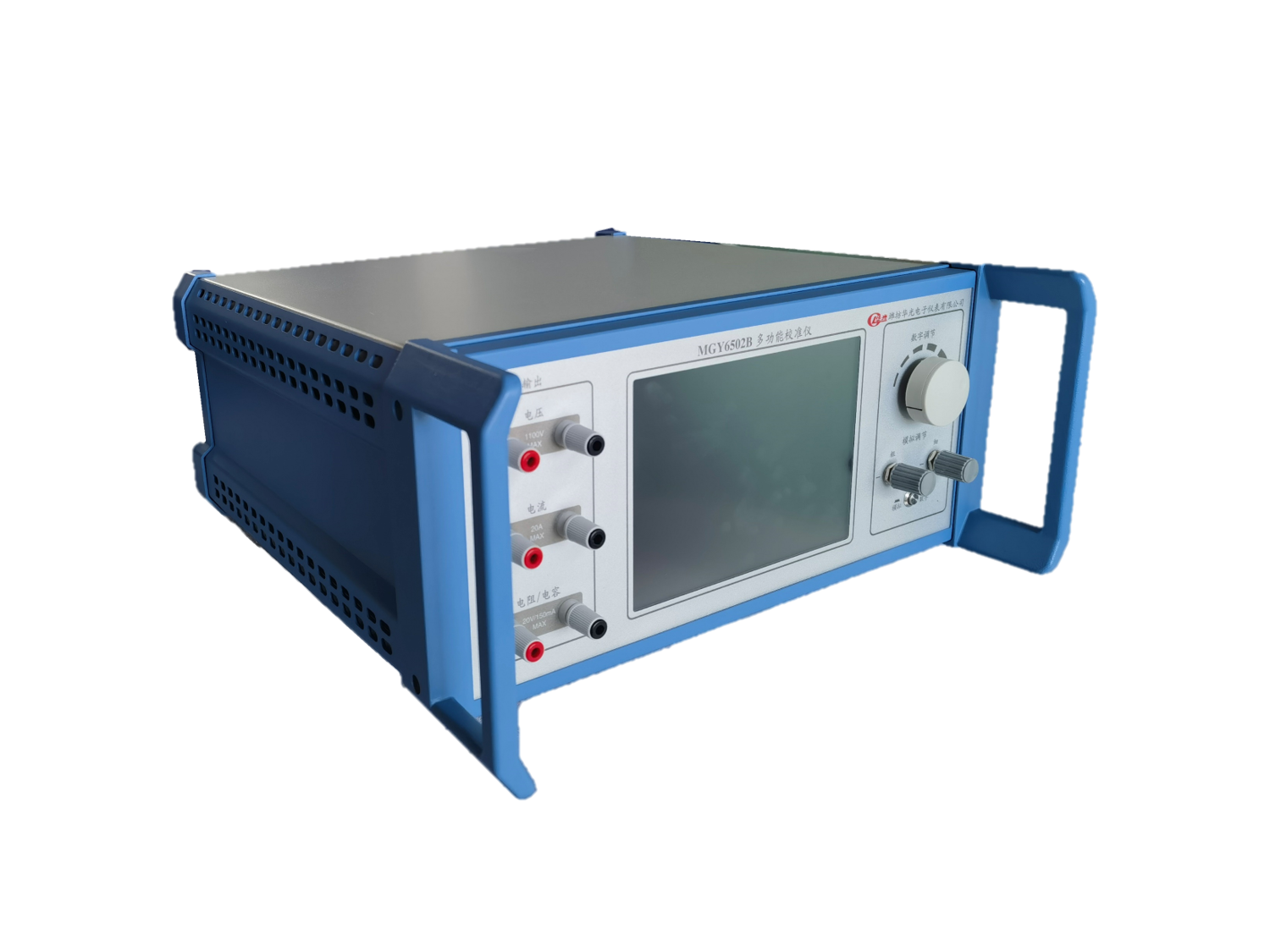

DO30 series three-meter/multimeter calibrator

HGZW-III fully automatic computerized photoelectric weft trimming machine

The HGZW-III fully automatic computerized photoelectric weft straightening machine is the latest digital intelligent weft straightening machine developed by our company that integrates high performance and high reliability, and has reached the world's advanced level. This machine adopts swing-type rotating photoelectric scanning detection, which has no detection blind area and can detect the angle and direction of weft deformation in a timely and accurate manner, thereby making the weft adjustment effect more sensitive and efficient. The weft yarn condition is displayed and recorded in real time using the human-machine interface (LCD screen). The brightness of the photoelectric scanning device is automatically adjusted, which can eliminate the influence of fabric variety, color and thickness on the scanning detection signal. At the same time, this machine also has functions such as automatic tracking of fabric speed, PID proportional control, ultra-low speed jam alarm and other functions. It is an ideal equipment for the textile printing and dyeing industry.

- Product description

-

HGZW-III fully automatic computerized photoelectric weft trimming machine

The HGZW-III fully automatic computerized photoelectric weft straightening machine is the latest digital intelligent weft straightening machine developed by our company that integrates high performance and high reliability, and has reached the world's advanced level. This machine adopts swing-type rotating photoelectric scanning detection, which has no detection blind area and can detect the angle and direction of weft deformation in a timely and accurate manner, thereby making the weft adjustment effect more sensitive and efficient. The weft yarn condition is displayed and recorded in real time using the human-machine interface (LCD screen). The brightness of the photoelectric scanning device is automatically adjusted, which can eliminate the influence of fabric variety, color and thickness on the scanning detection signal. At the same time, this machine also has functions such as automatic tracking of fabric speed, PID proportional control, ultra-low speed jam alarm and other functions. It is an ideal equipment for the textile printing and dyeing industry.Main Specifications

Width 1600-4000mm Total power consumption of power supply 380±10% 50Hz Max 1000vA Scanning detection head and quantity Swinging and rotating photoelectric scanning detection heads 4-8 pcs Light source and quantity Automatic dimming lens light-emitting head (or infrared light source) 4-8 pcs Adapt to vehicle speed 5-130m/min Fabric yarn density 36-120 yarns/inch Correction roller form Three straightening rollers, two or three straightening rollers (active or passive) Φ100-Φ150mm Detection accuracy 0.49° maximum correction ability Weft skew correction 900mm Arc weft correction 250mm Motor drive method Frequency conversion control, relay control Keywords:- HGZW-III型全自动电脑光电整纬机